A plethora of the world’s obsolete phones, decommissioned laptops, and other discarded electronics represent a collective reservoir of rare earth elements (REEs). Nevertheless, extracting and reclaiming these increasingly valuable materials is a challenging endeavor.

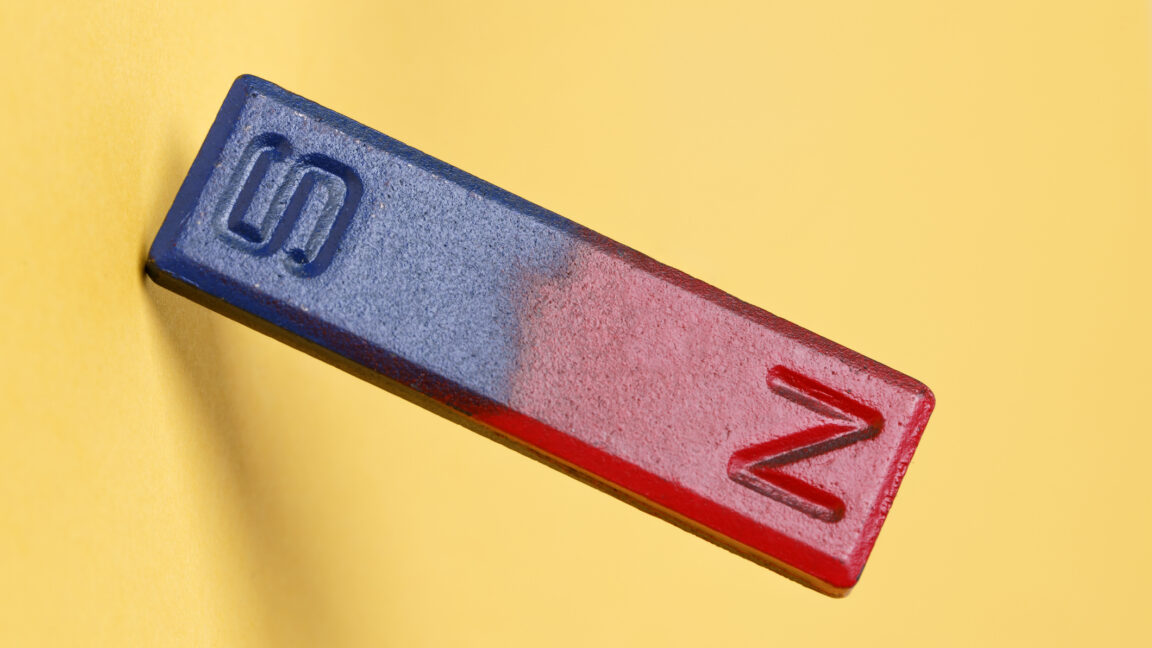

Nonetheless, a coalition of researchers claims to have pioneered a method for isolating REEs from waste—using magnets in this instance—that is comparatively simpler, consumes less energy, and is not as emission- and pollution-heavy as existing techniques. The group published a paper detailing this approach in the Proceedings of the National Academy of Sciences.

In essence, the technique employs an electric current to swiftly heat waste magnets to extremely high temperatures, while utilizing chlorine gas to interact with the non-REEs present, keeping them in the vapor phase. James Tour, one of the co-authors and a materials science and nanoengineering professor at Rice University, asserts that this research could assist the United States in fulfilling its increasing demand for these elements.

“The nation’s hustling to explore how we can obtain these [REEs],” he states. “And, in our perspective, they are all in our waste… We have it right here, just extract it straight from the waste.”

It’s heating up in here

In 2018, Tour and his associates found out that this swift heating technique, known as flash joule heating, can convert any carbon source—including coal, biochar, and assorted plastics—into graphene, which is a very thin, resilient, and conductive substance.

Expanding on this, in 2023, they established a method that integrates flash joule heating and chlorine. In this research, they determined the Gibbs free energy, which reflects the reactivity of a material, for the oxide form of all 17 REEs and nine prevalent oxides found in REE waste.

Crushed waste magnets are placed on a carbon-made platform and are enclosed by a glass chamber. An electric current passes through the platform, rapidly generating extreme heat, reaching thousands of degrees Celsius within seconds. Chlorine gas is then introduced into the chamber, forming chlorides of undesired elements such as iron and reducing their boiling points.